Challenge

A global manufacturer of custom-engineered foam-based components, products and packaging was looking to automate a fully manual process for slipping foam “buns” into standard dimensions for production. Within the original process, workers had to push and lift large blocks of foam “buns” weighing hundreds of pounds to get them separated after sawing. Not only was the process labor intensive, it slowed down overall production.

Solution

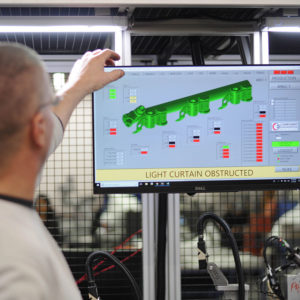

Orka Automation collaborated with the engineering and production teams in designing an automated solution that streamlined the material transfer process, split the foam bun into programmed recipes, eliminated arduous labor requirements and provided 100% variable data collection and reporting to meet changing regulatory requirements.

Outcomes and Benefits

Holistic team-based approach improved production through-put and capacity, reduced labor requirements and improved worker safety / reduced worker injuries.

In addition, foam buns are inspected for dimensional tolerance and dispositioned prior to transitioning to production, further improving overall production efficiencies.