A few weeks ago we shared some of the top manufacturing tech advancements featured at the recent Advanced Manufacturing Expo, as well as in various industry publications we stalk for the latest information. With so many advancements to share, we split our list into two parts. And now the moment you’ve been waiting for!

2020 | Top Tech Trends for Manufacturing Part 2

6. Low-Code Platforms. For those of us with already stretched IT departments and budgets, low-code platforms maybe the next best thing since sliced bread. These new platforms give you the basic coding, which can easily be tweaked and customized to your needs via a good programmer. (Note – These aren’t always the answer, but for simpler applications, they might be just what you need.)

7. 3D Scanning and Printing. 3D technologies are improving by leaps and bounds, and the next generation of 3D scanners will make it easier for you to turn physical things into virtual things in a fraction of the time. Great opportunity for reverse engineering, additive manufacturing, and more.

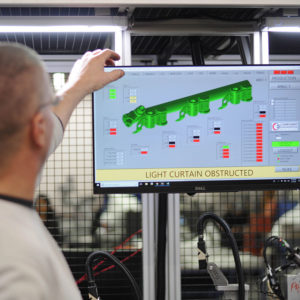

8. Visual Performance Feedback On The Floor. Providing feedback on how production is going after the fact doesn’t help anyone. And, we know that people don’t have time to read anymore. (Reference my note in #5 above.) Outfitting the production floor with monitors providing real-time production status in a visual format helps production teams adjust in the moment, minimizing rejects and reworks.

9. Autonomous Bots. This new generation of Bots is experiencing a higher level of acceptance and appreciation than their non-commercial autonomous car counterparts. Manufacturing companies of all sizes are leveraging these speedy little buggers for material handling tasks throughout the production process.

10. Skilled Trades for Industry 4.0 and 5.0. Robots are only coming for the jobs that humans don’t really want to do anyway – so put your mind at ease. In addition to handling the less desirable jobs, they are freeing up the workforce to focus on the next generation of skills companies will need to operate at a globally competitive level. The time for “Trade Education” and getting your workforce up to speed on next generation outputs is now. Don’t wait for the future to arrive. Get your team ready for the workforce now.

With so many advancements on the horizon, its the perfect time to try automation in your manufacturing process. Contact us for a free discovery conversation. And, maybe we’ll see you or your team in one of the many skilled trade courses in West Michigan. Expertise requires lifetime learning as a core foundation, and we’re excited about so many new things to learn about.