CLIP INSTALLATION AND INSPECTION PLATFORM

Precision in Every Panel.

In industries like automotive, appliances, and medical devices, flawless panel assembly isn’t just a goal—it’s a necessity. It affects everything from safety and performance to aesthetics and cost-efficiency.

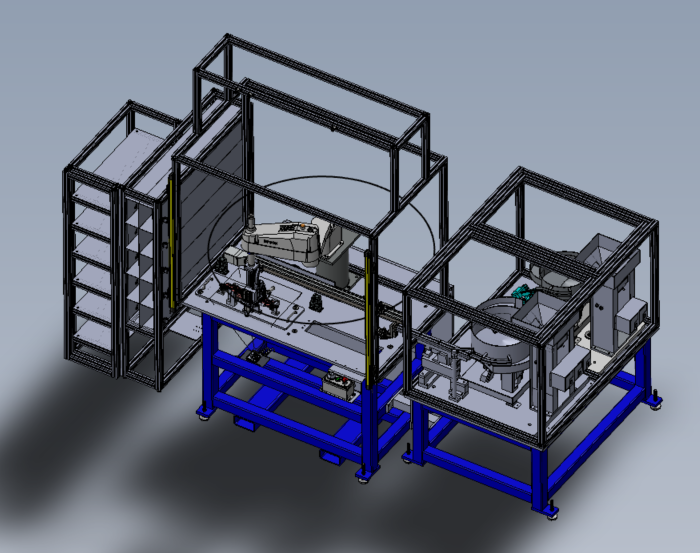

Our automated Clip Assembly and Inspection Platform transforms the process with a modular, adaptable workstation platform that ensures consistent quality, reduces errors and rework, and accelerates production. By automating installation and inspection, manufacturers can achieve continuous, high-precision operation while freeing skilled workers for more complex tasks—driving faster ROI and greater profitability.

benefits to your business and your outputs

All-in-One Workstation

- Seamlessly install, inspect, and barcode multiple components in one streamlined setup.

Precision-Driven Performance

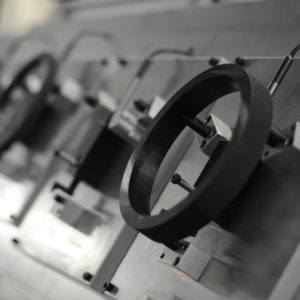

- Ensure perfect alignment and secure fastening for every clip, every time.

Boost Productivity

- Reduce cycle times and eliminate rework with intelligent automated inspection and real-time quality control.

Flexible Integration

- Adaptable to various panel types, sizes, and production environments.

Human-Centered Design

- Automation can reduce the physically demanding aspects of manual clip installation, creating more ergonomic and safer working environments for employees.

TESTING STANDARDS

Each clip undergoes rigorous inspection to ensure compliance with quality and performance requirements. Our system verifies:

- Correct clip attachment orientation and depth

- Presence of required components

- Component color accuracy

These checks help guarantee consistent assembly quality and reduce the risk of downstream defects.

PLATFORM PERFORMANCE HIGHLIGHTS

- 100% inspection across all check points

- 100% traceability

- Capable of installing and inspecting clips on multiple sub-assemblies on the same machine

PLATFORM FEATURES AND CUSTOMIZATION OPTIONS

STANDARD FEATURES

- Extrusion or tubular steel frame with enclosure and safety features

- Component Engineering precision part specific nesting fixtures

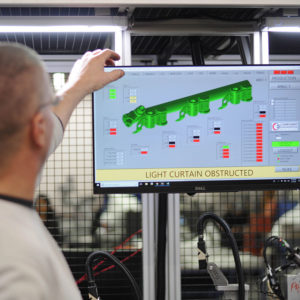

- Standard Allen Bradley PLC and 7” HMI

- Operator training and post-installation support

CUSTOMIZATION OPTIONS

- Assembly – Welding

- Quality Control – Vision

- Traceability – Barcoding, Laser Marking, Label Apply

- Material Movement – Bowl Feeder

- Data Collection and Reporting – Variable Data Display with Report Options, Statistical Process Control (SPC) Trending

- Other – Storage for multiple part nesting fixtures

RESOURCES AND INFORMATION

- DOWNLOAD – Clip Installation and Inspection Product Sheet

- VIEW – Our Case Study Video

- READ – Our Customer Case Study

Perfect panels start with perfect clips — installed and inspected with confidence.