DIALFLEX PLATFORM

Engineered for precision, speed, and adaptability.

Maximize your manufacturing efficiency with DialFlex™, the industrial-grade rotary dial table platform built for high-performance automated environments. Whether you’re assembling, inspecting, or machining, DialFlex™ ensures consistent, high-quality results with minimal downtime.

Engineered for flexibility, this platform adapts seamlessly to evolving production demands—making it the ideal solution for manufacturers who require scalable automation without compromising precision or reliability.

BENEFITS TO YOUR BUSINESS AND YOUR OUTPUTS

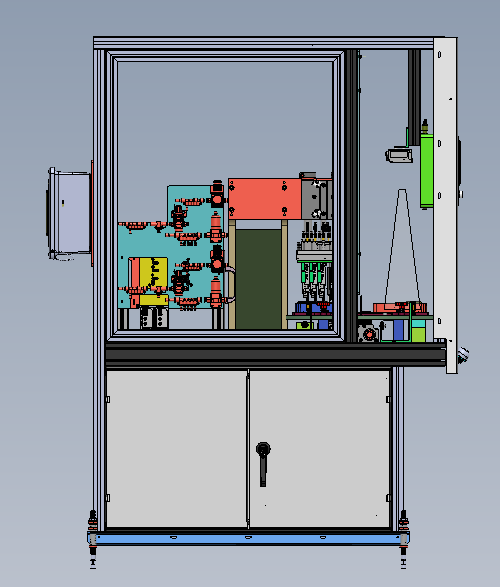

Industrial-Grade Rotary Dial Table

- Precision-engineered rotary dial table ensures consistent, reliable performance and smooth part transitions—ideal for high-throughput automated assembly lines.

Two Modular Base Units

- Accelerates workstation design and setup, reducing engineering time and speeding up deployment.

Custom Tooling Packs

- Tailored for specific processes (assembly, welding, inspection, testing, marking,) enhancing process accuracy and efficiency by aligning tools with exact production needs.

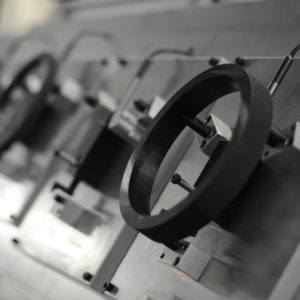

Interchangeable Nesting Fixtures

- Quick-swap nesting fixtures supports multiple part types and enables fast changeovers, maximizing workstation flexibility and uptime.

Scalable Workstation Options

- Configurable as single-station or multi-station work cells to adapt to your production scale—from manual operator-assisted setups to fully automated robotic cells.

Simultaneous Load & Process

- Rotary dial enables concurrent part loading and processing, minimizing cycle time and boosting overall throughput without increasing footprint.

PLATFORM FEATURES AND CUSTOMIZATION

STANDARD FEATURES

- Extrusion or tubular steel frame with enclosure and safety features.

- Component Engineering precision part-specific nesting fixtures.

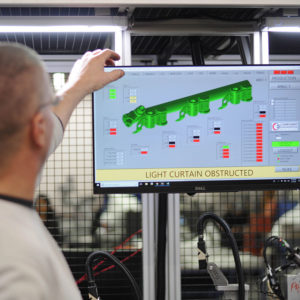

- Standard Allen Bradley PLC and 7″ HMI.

- Operator Training and post-installation support.

BASE UNITS

- Base Unit 1 – 24″W x 40″D x 70″H; 32″-40″ Worktable Height; and Part Holding up to 10″W x 12″D x 4″H

- Base Unit 2 – 48″W x 40″D x 70″H; 32-40″ Worktable Height; Part Holding up to 20″W x 24″D x 10″H

TOOLING PACKS

- Manufacturing – Assembly, dispensing, heat staking, ultrasonic welding, other.

- Inspection & Testing – Auto gage, vision inspection, electric current and voltage, lead, light, and final function testing.

- Marking – Barcoding, laser marking, and data collection and reporting.

RESOURCES AND INFORMATION

- DOWNLOAD – DialFlex Platform Product Sheet

Efficiency in Motion. Precision in Every Turn.