fuel rail inspection platform

Ensuring precision fuel delivery for peak engine performance.

Fuel rails are essential components of modern fuel injection systems. These high-pressure, hollow tubes serve as a pressurized reservoir, ensuring a consistent and even supply of fuel to each injector. This stability is critical for optimal engine performance, improved fuel efficiency, and reduced emissions.

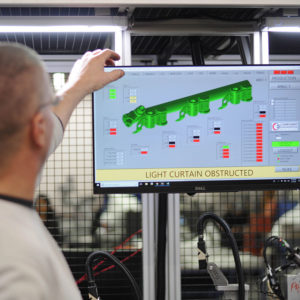

Our automated Fuel Rail Inspection Platform delivers 100% inspection across all check points in 30-seconds or less, ensuring high performance engines perform consistently.

BENEFITS TO YOUR BUSINESS AND YOUR OUTPUTS

100% Inspection in Under 30 Seconds

- Rapid, automated inspection ensures every fuel rail meets quality standards without slowing down production.

Precision Fuel Delivery Assurance

- Verifies consistent fuel flow to injectors, supporting peak engine performance and reliability.

Improved Fuel Efficiency & Emissions Control

- Ensures optimal combustion, helping manufacturers meet environmental regulations and reduce fuel consumption.

Reduced Rework and Scrap Costs

- Early defect detection minimizes downstream failures, saving time and resources.

Enhanced Product Quality and Consistency

- Delivers uniform inspection results across all units, boosting customer confidence and brand reputation.

Scalable Integration into Production Lines

- Easily adapts to existing workflows, supporting high-volume manufacturing without disruption.

Labor Optimization

- Frees skilled technicians from repetitive tasks, allowing them to focus on innovation and value-added activities.

Faster Time-to-Market

- Streamlined inspection process accelerates delivery timelines and improves responsiveness to market demand.

TESTING STANDARDS

We rigorously test fuel rails to meet customer-defined performance criteria.

- True position, profile, and perpendicularity of mounting brackets, injector cups, inlets, connectors, pressure sensor ports, and wire harness brackets.

- Spread check

- End-cap height check

- Cross-strap height check

- Injector cup notch orientation check

- Clear-through / Diameter Check

PLATFORM PERFORMANCE HIGHLIGHTS

- 100% inspection across all check points in < 30 seconds

- 100% traceability

- Repeatability and reproducibilty < 10% on all features – tolerances from 0.03mm to 1.00mm

- Correlation to CMM < 0.10mm

- Capable of running RH/LH parts and V6/V8 parts on the same machine without mechanical changeover

- Current machines running on average of 250,000 units / year – 1 machine / 1 shift / 1 operator

- Average inspection cost / unit < $0.50

PLATFORM FEATURES AND CUSTOMIZATION OPTIONS

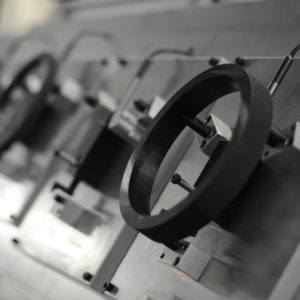

Standard Features

- Extrusion or tubular steel frame with enclosure and safety features

- Component Engineering precision part specific nesting fixtures with pneumatic clamping

- Standard Allen Bradley PLC and 7″ HMI

- Operator training and post-installation support

Customization Options

- Quality Control – Vision, LVDT, Laser, TruPosition™ Probe with Custom Tip

- Traceability – Barcoding, Laser Marking, Label Apply, Data Collection and Reporting

- Material Movement – Robot Load / Unload, Conveyance

- Data Collection and Reporting – Variable Data Display with Report Options, Statistical Process Control (SPC) Trending

RESOURCES AND INFORMATION

Ensuring optimal performance from high-performance engines.