DIE CAST inspection platform

Precision You Can Trust in Every Die-Cast Part

Die-cast components power everyday products and critical industries—from automotive and aerospace to consumer electronics and medical devices. Known for their precision, strength, and high strength-to-weight ratio, die casting is ideal for producing complex shapes with fine detail. Ensuring these parts meet exacting standards is essential to performance and reliability.

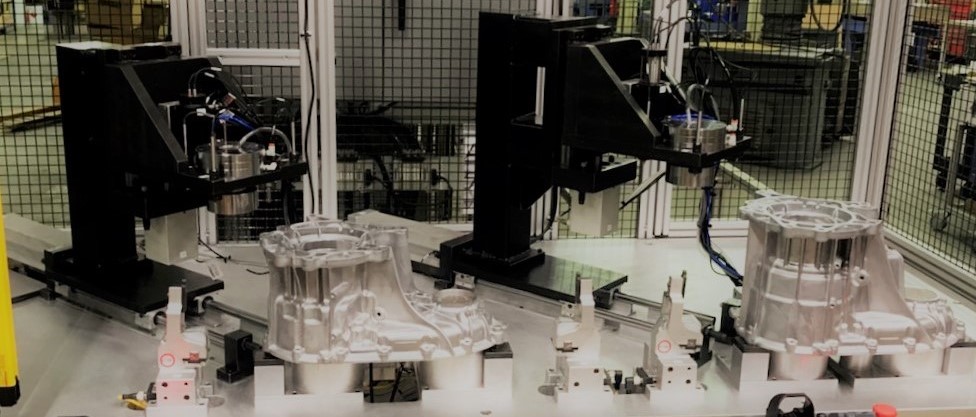

Our automated Die Cast Inspection Platform delivers 100% inspection accuracy, detecting defects and verifying dimensions with speed and consistency. With integrated pre- and post-inspection automation, we help manufacturers boost efficiency and adapt to changing demand.

BENEFITS TO YOUR BUSINESS AND YOUR OUTPUTS

Boosted Operational Efficiency

- Automated inspection reduces manual labor and speeds up quality control.

- Pre- and post-inspection automation streamlines workflows, minimizing bottlenecks.

- Enables faster turnaround times for high-volume production.

Unmatched Quality Assurance

- Achieves 100% inspection accuracy, ensuring every part meets exacting standards.

- Detects surface defects, dimensional deviations, and structural flaws with precision.

- Reduces the risk of costly recalls or product failures in critical industries.

Increased Profitability

- Minimizes scrap and rework costs by catching defects early.

- Enhances customer satisfaction and retention through consistent product quality.

- Supports lean manufacturing goals by optimizing resource use.

Scalable & Flexible Production

- Easily adapts to changing demand and product variations.

- Ideal for industries with tight tolerances and complex geometries, such as aerospace and medical devices.

- Future-proof solution that grows with your business.

Compliance & Risk Reduction

- Helps meet industry standards and regulatory requirements.

- Provides traceable inspection data for audits and quality documentation.

- Reduces liability by ensuring parts meet safety and performance benchmarks.

testing standards

To ensure die-cast parts meet stringent specifications, our inspection platform combines contact and non-contact automation technologies for rigorous, real-time quality control.

DIMENSIONAL VERIFICATION

We ensure every part meets customer-defined tolerances with high accuracy:

- Clear-through / Diameter Check

- Cylindricity

- Inner/Outer Diameter (ID/OD)

- Parallelism

- Perpendicularity

- True Position

DEFECT DETECTION

Advanced inspection algorithms identify even the smallest defects:

- Blistering

- Feature Absence or Presence

- Porosity on Machined Surfaces (down to 0.2 mm)

- Surface Defects

- Tight Tolerance Defect Detection

platform performance highlights

- 100% inspection across all check points

- 100% traceability

- Repeatability and reproducibility < 10% on all features – tolerances from 0.015mm to 1.0mm

- Correlation to CMM < 0.10mm

- Inspected to the same criteria and standards of a traditional CMM process

- Capable of running RH/LH parts on the same machine without mechanical changeover

PLATFORM FEATURES AND CUSTOMIZATION OPTIONS

STANDARD FEATURES

- Extrusion or tubular steel frame with enclosure and safety features

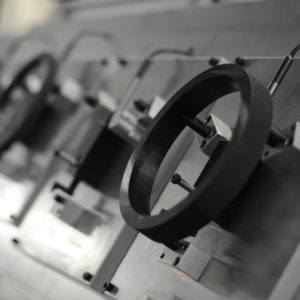

- Component Engineering precision part specific nesting fixtures with pneumatic clamping

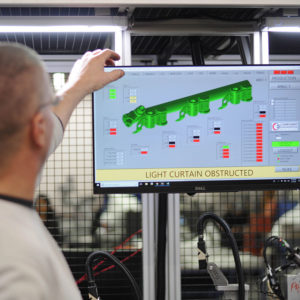

- Standard Allen Bradley PLC and 7″ HMI

- Operator training and post-installation support

CUSTOMIZATION OPTIONS

- Quality Control – Mahr Metrology Air Gaging Technology, Vision, LVDT, Laser, TruPosition probe with custom tip

- Traceability – Barcoding, Laser Marking, Label Apply, Data Collection and Reporting

- Material Movement – Robot Load / Unload, Conveyance

- Additional Enhancements – Product Packout

RESOURCES AND INFORMATION

Advanced Dimensional & Defect Detection for Die Cast Parts