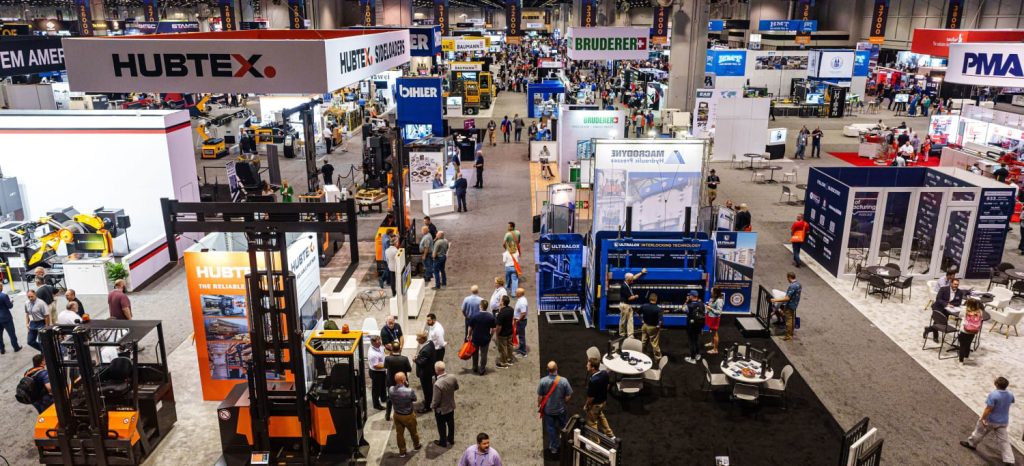

FabTech remains North America’s leading event for metal forming, fabricating, welding, and finishing. This year’s show was bigger than ever, with over 1,700 exhibitors and a record-breaking 50,000 attendees exploring the latest innovations in manufacturing technology. From AI-driven automation to high-precision lasers and collaborative robots (cobots), the buzz was all about solving workforce and productivity challenges with smarter tools.

At Orka Automation, we attended with a clear focus: understanding how these trends impact our customers and how we can help them stay ahead. Here’s what stood out to us:

Whether you’re exploring automation, reshoring, or scaling sustainably, we’re here to help.

Start a conversation: [email protected]

Learn more: orkaautomation.com | cequalitysolutions.com

Follow us on LinkedIn: ORKA Automation; Component Engineering Quality Solutions

Our team is rooted in operational and technical expertise – blended with new team members that bring extensive industry and general business experience. We believe this makes us stronger partners – not only looking for how we can help with the technical bits, but how we can positively impact overall operational and business outcomes.

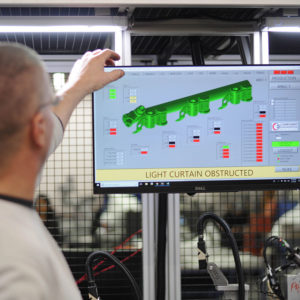

Quality is an integral part of our DNA. Our sister company, Component Engineering, is a recognized leader in fixtures, gages, and automated quality inspection machines. By integrating this heritage and expertise throughout our process and resulting solutions, we ensure quality outcomes for our customers.

We start by listening to understand and looking at your total process from start to finish – machines and people. Our approach to problem solving blends creativity and technical expertise, and our customers always come first – from concept through post-installation.