PLATFORMS

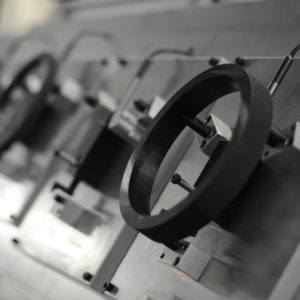

SCALABLE MODULAR PLATFORMS POWERED BY AUTOMATION

Modular machine platforms, combined with automation, offer a flexible and efficient approach to manufacturing.

These platforms allow for customization, scalability, and easier integration of different machine functions, leading to faster development times and reduced costs.

PLATFORM BENEFITS

Flexibility and Scalability

Modular design allows for customization and adaptation to changing production needs. Machines can be built with a few modules and expanded as needed, and individual modules can be reconfigured or replaced, making them future-flexible.

Faster Development. Reduced Costs

Modular components can be developed, built, and tested independently, shortening the overall time to install and reducing costs associated with custom machine building.

Improved Efficiency and Maintainability

Modular platforms enable easier maintenance and repairs, as individual modules can be serviced or replaced without disrupting the entire production line.

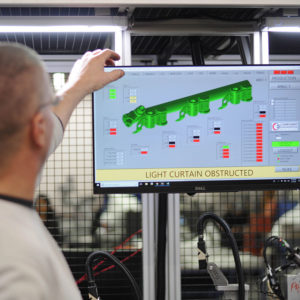

Enhanced Operational Integration

Modular platforms facilitate the integration of automation components, such as sensors, actuators, and control systems, allowing for seamless communication and control across the entire system.

Industry and Application Adaptability

Modular platforms can be applied across multiple industries, including automotive life science, commercial vehicles, and electronics, with customized solutions tailored to specific needs.

Standardized Interfaces

Standardization of interfaces between workstations simplifies integration and facilitates collaboration between different automation providers throughout your manufacturing line.

Revolutionize Your Workflow with Modular Automation Platforms

Empower your operations with scalable, customizable solutions designed for efficiency and innovation.