ROLL FORM inspection platform

Precision in Every Profile: Ensuring Quality in Roll-Formed Components

Roll-formed materials are essential across industries—from automotive and appliances to renewable energy, construction, and infrastructure. The roll forming process delivers high-strength, cost-effective components with exceptional dimensional accuracy, making it ideal for structural parts and sub-assemblies.

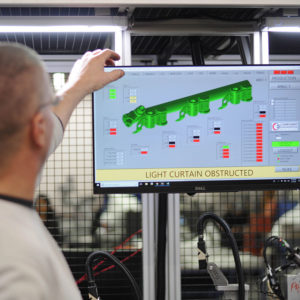

Our Roll Form Inspection Platform is built to ensure every part meets exacting standards for dimensional accuracy, functional performance, surface finish, and material integrity. With automated inspection across multiple checkpoints, you gain consistent, dependable quality control—critical for high-performance structural components and precision sub-assemblies. When reliability matters, our platform delivers the confidence you need.

BENEFITS TO YOUR BUSINESS AND YOUR OUTPUTS

Enhanced Product Quality

- Ensures dimensional accuracy, surface finish, and material integrity across all components. Reduces defects, rework, and scrap—leading to higher customer satisfaction and fewer warranty claims.

Automated, Scalable Inspection

- Supports high-throughput production with automated multi-point inspection. Easily integrates into existing roll forming lines, scaling with production demands.

Faster Time-to-Market

- Speeds up quality assurance processes without compromising precision. Enables quicker validation of new designs and materials for faster deployment.

Cost Efficiency & ROI

- Minimizes labor-intensive manual inspections, freeing skilled workers for higher-value tasks. Reduces operational costs through early defect detection and streamlined quality control.

Improved Operational Reliability

- Delivers consistent, repeatable inspection results—critical for structural components. Enhances process stability and reduces downtime due to quality-related issues.

Cross-Industry Versatility

- Ideal for automotive, construction, appliances, renewable energy, and infrastructure sectors. Supports diverse roll-formed profiles and sub-assemblies with adaptable inspection criteria.

testing standards

Our advanced inspection platform is engineered to verify the dimensional accuracy, functional reliability, and material integrity of roll-formed components—ensuring every part meets your performance standards.

Testing Standards

- True position verification of mounting holes

- Profile measurements for tubes and brackets

- Go/No-Go checks for all other holes

- Temperature monitoring

- Automated temperature and dimensional compensation

Additional Testing Experience

- Weld nut presence detection

- Blue/Red Light Laser Scanning for Weld Inspection

platform performance highlights

- 100% inspection across all check points

- 100% traceability

- Repeatability and reproducibility < 10% on all features – tolerances from 0.015mm to 1.0mm

- Correlation to CMM < 0.10mm

- Inspected to the same criteria and standards of a traditional CMM process

- End-of-line inspection eliminates the need for time consuming fixtures or CMM part checks.

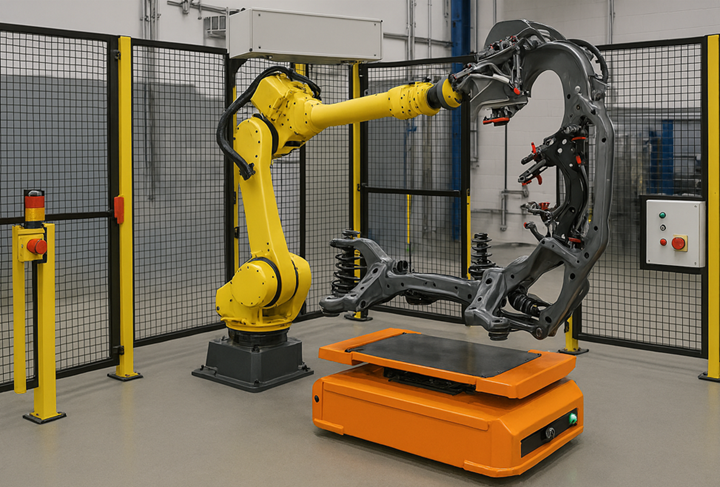

- Designed to support at-build or future integration of robot part load / unload.

- Cycle time enables future capacity expansion without additional inspection costs.

PLATFORM FEATURES AND CUSTOMIZATION OPTIONS

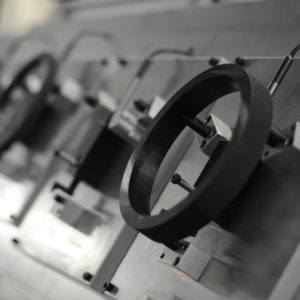

STANDARD FEATURES

- Extrusion or tubular steel frame with enclosure and safety features

- Component Engineering precision part specific nesting fixtures with pneumatic clamping

- Standard Allen Bradley PLC and 7″ HMI

- Operator training and post-installation support

CUSTOMIZATION OPTIONS

- Quality Control – Vision, LVDT, Laser, TruPosition™ Probe with Custom Tip

- Traceability – Barcoding, Laser Marking, Label Apply, Data Collection and Reporting

- Material Movement – Robot Load / Unload, Conveyance

- Data Collection and Reporting – Variable Data Display with Report Options, Statistical Process Control (SPC) Trending

RESOURCES AND INFORMATION

- DOWNLOAD –Roll Form Inspection Platform Sheet

Quality Assurance for Roll-Formed Parts Across Industries