There are many things to consider when designing a new production line or updating an existing one. Many of our new customers are small to medium sized businesses that have continued to expand their production lines, but are now in a situation where they are looking toward automation to improve overall efficiencies and outputs. Automation can be a great option, but before we execute, we take a holistic view of their overall facility to see where we can incorporate Lean practices first, and automate where it makes the most sense. Often we’ve found that the most valuable deliverable we can provide our customers is perspective and recommendations for streamlining the flow of their production process before adding automation.

The Flow of the Factory Flow

To maximizing efficiencies on the floor the first step is starting with the big picture.

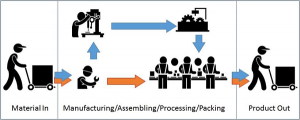

- Material In / Receiving

- What’s coming in?

- How many pieces are there?

- How often are components arriving?

- Are there inventory or quality inspection requirements for incoming components?

- How do incoming materials get from receiving to production?

- Manufacturing / Assembling / Processing / Packing

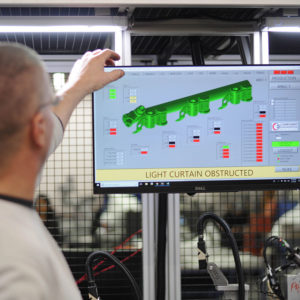

- Are your work cells employee operated or automated?

- If work cells are employee operated, are there ergonomic features we should be consider, i.e. do work cells need to flexible for handedness and worker height?

- Do you have equipment, components or people who serve multiple lines?

- How are you managing work in process?

- What are your production key performance indicators?

- Product Out / Shipping

- What’s going out?

- How big is it?

- How does it get from manufacturing to shipping?

- Are there special packaging considerations?

- Overall

- Are you starting with a blank slate, or do you need to work around existing infrastructure?

- Do you need to think about future flexibility? (The answer to this question is always, Yes!)

Aligning What You Want and What You Need

Perspective is a key benefit of viewing your production process from the outside in. Often on a production walk-through, our team will see things that our customers do not – primarily because we are viewing the process with fresh eyes. Our unique Discovery Process evaluates what you ask for and provides recommendations for factory flow and process improvements, controls integration and automation options based on what you need current and long-term. We find that by providing customers with simple, impactful options, including timelines and price points, they can strategically plan investments and upgrades, making them more efficient in the short term, and competitive for the long term.

In Summary…

- Better for your Business – Well designed production facilities results in a seamless flow of people, material and information.

- Better for your Employees – Taking a holistic view of your production facility and processes also gives you the opportunity to identify and implement simple updates that create efficiencies, incorporate ergonomic elements, and create a safer workplace for your employees.

- Better for your Customers – A well designed factory flow delivers consistent quality components and finished products, and peace of mind for your customers.

To request a free Discovery Evaluation, contact us today! We’d be happy to partner in reviewing and providing recommendations to help streamline your factory flow.

Check back next month when we take a deeper dive into additional considerations for production line-layout strategies that maximize outputs and minimize human struggle.