Manufacturers today need to run faster, cheaper and leaner to meet customer demands and remain profitable and competitive in a global economy. If you’ve started to think about automating parts of your manufacturing process, but don’t know where to start or how to justify the business decision, you aren’t alone.

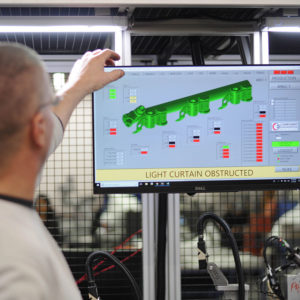

While many manufacturers think that automation is about the equipment – robot arms, conveyors, cameras, etcetera – those who have integrated automation successfully understand that these are just tools to achieve a desired end result.

While many manufacturers think that automation is about the equipment – robot arms, conveyors, cameras, etcetera – those who have integrated automation successfully understand that these are just tools to achieve a desired end result.

Taking the time to understand your business goals and your manufacturing process – including suppliers, equipment and people – is an essential first step we take when helping customers make an informed, smart decision for their business.

Before we talk about automation, let’s understand…

Your process

- Understand why you do what you do

- Look at your manufacturing process from start to finish

- Identify potential ripple effects of making changes – how will changing one activity in your process impact something else – positively or negatively

- List, prioritize and align opportunities for manufacturing efficiencies with your business goals, people and budget

- Plan for what you need now, and anticipate what you might need 3-5 years down the road

Your short and long-term business goals

- Improved response time?

- Increased throughput?

- Reduced errors?

- Consistent, traceable quality inspection?

- Increased capacity?

- Workforce supplementation?

- Profit objectives?

Your people

- Does your team have the right skillset for today and tomorrow?

- Will your team embrace change?

- What’s your plan for getting the team involved in the evaluation, design and execution of manufacturing efficiencies?

Your budget

- Understanding your budget at the front end can help drive proposed solutions that maximize your return on investment.

- You don’t have to do it all at once. Small changes can yield significant improvements in efficiencies and throughput, making it easier to justify additional investment in the future.

Improving your processes and integrating various degrees of automation within your manufacturing process can, and will, improve your ROI and increase your competitiveness.

Asking questions and clearly defining your goals before you start on your project ensures a successful outcome.

If you are just starting to consider automation and are uncertain where to begin, or already on the journey and need additional support, call or email us! We’d love to start with a conversation. [email protected]

616-888-2369